Plastic Welding Machine for Small Auto Parts

Product Description

According to The Products: According to The Products Specification: According to The Products Trademark: KEBER Origin: China Hot melting plastic welding machinery

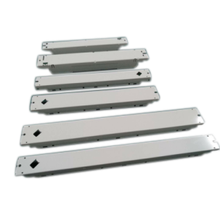

Plastic Welding Machine for small auto parts

Keber hot melting Welder for electronics industry

Main features:

1. PLC programmed control systems and human-computer Interface for adjusting welding parameters.

2. Welding area and welding range are wider.

3. Double starting buttons improve the security.

4. Integrated design that can move conveniently and efficiently, Beautiful and coordinated.

Riveting Welding Machine

Specifications:

Application: Cell-phone antenna, cell-phone housing,

Connectors, MP3, computer interior parts.

Place of origin: Suzhou, China

Specifications:

Ultra-high power utilization ratio transducer

Intelligent computer control

High precision.

Stable working

High precision automatic Ultrasonic welding machine

CE. SGS, ISO9001 passed.

Adopt American original transducer, output power is strong and stable(2) titanium alloy amplitude transformer, solid and durable(3) straight bearings, precision fine-tuning installations, high performance(4) the full range of high-quality imported components, quality assurance(5) number of Welding Machine at the same time driving, where appropriate, withStep in the process, save time. (6) suitable for very large plastic welding.

Principle of Plastic Welders:

Plastic welders operate by inducing ultrasonic frequencies in plastic components that is converted into heat between the welded plastic laminates. Frictional heat is produced so that thermoplastic parts melt and an insoluble connection between parts is forged in a very short period of time. The melting points of both working pieces is nearly equivalent which helps to form a uniform weld area. The welded area is usually as strong as the matrix material.

Application fields:

Widely used in the automotive industry, electronic industry, medical industry, household appliances, woven apparel, office supplies, packaging industry, toy industry and so on.

Such as plastic body parts, car doors, car dashboard, lights, mirrors, sun visor, interior parts, filters, reflective material, reflective spike, bumper, cable, motorcycle plastic filter, radiator, tanks, pallet plates.

Plastic electronics: Prepaid water meters, communications equipment, atheism phone, mobile phone accessories, cell phone case, battery case, charger, maintenance valve regulated lead-acid batteries, 3-inch floppy disk, U disk, SD card, CF card, USB connectors, Bluetooth.

Toys, stationery: Folder, album, folding boxes, PP hollow board, pen loops, ink cartridges, toner cartridges.

Medical Daily: Watches, kitchen utensils, oral liquid bottle, drip caps, mobile phone accessories, gold soft brush, daily necessities, health supplies, children's products, air mattresses, clothes hangers, tool holder, coffee pot, cover and Civil speaker grille metal surface. Contact us if you need more details on Car Door Welding Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Spin Welding Machine、Hot Plate Welding Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Plastic Welding Machine for small auto parts

Keber hot melting Welder for electronics industry

Main features:

1. PLC programmed control systems and human-computer Interface for adjusting welding parameters.

2. Welding area and welding range are wider.

3. Double starting buttons improve the security.

4. Integrated design that can move conveniently and efficiently, Beautiful and coordinated.

Riveting Welding Machine

Specifications:

Application: Cell-phone antenna, cell-phone housing,

Connectors, MP3, computer interior parts.

Place of origin: Suzhou, China

Specifications:

Ultra-high power utilization ratio transducer

Intelligent computer control

High precision.

Stable working

High precision automatic Ultrasonic welding machine

CE. SGS, ISO9001 passed.

Adopt American original transducer, output power is strong and stable(2) titanium alloy amplitude transformer, solid and durable(3) straight bearings, precision fine-tuning installations, high performance(4) the full range of high-quality imported components, quality assurance(5) number of Welding Machine at the same time driving, where appropriate, withStep in the process, save time. (6) suitable for very large plastic welding.

Principle of Plastic Welders:

Plastic welders operate by inducing ultrasonic frequencies in plastic components that is converted into heat between the welded plastic laminates. Frictional heat is produced so that thermoplastic parts melt and an insoluble connection between parts is forged in a very short period of time. The melting points of both working pieces is nearly equivalent which helps to form a uniform weld area. The welded area is usually as strong as the matrix material.

Application fields:

Widely used in the automotive industry, electronic industry, medical industry, household appliances, woven apparel, office supplies, packaging industry, toy industry and so on.

Such as plastic body parts, car doors, car dashboard, lights, mirrors, sun visor, interior parts, filters, reflective material, reflective spike, bumper, cable, motorcycle plastic filter, radiator, tanks, pallet plates.

Plastic electronics: Prepaid water meters, communications equipment, atheism phone, mobile phone accessories, cell phone case, battery case, charger, maintenance valve regulated lead-acid batteries, 3-inch floppy disk, U disk, SD card, CF card, USB connectors, Bluetooth.

Toys, stationery: Folder, album, folding boxes, PP hollow board, pen loops, ink cartridges, toner cartridges.

Medical Daily: Watches, kitchen utensils, oral liquid bottle, drip caps, mobile phone accessories, gold soft brush, daily necessities, health supplies, children's products, air mattresses, clothes hangers, tool holder, coffee pot, cover and Civil speaker grille metal surface. Contact us if you need more details on Car Door Welding Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Spin Welding Machine、Hot Plate Welding Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Automotive Plastic Parts Welding Machine

Premium Related Products

Other Products

Hot Products

DC MMA Machine for Tube UseIGBT Inverter AC/DC TIG Welding MachineIGBT Inverter Pulse TIG Welding Machine (WSM7-500)Inverter Carbon-Arc Air Gouging MachineInverter DC Multi-funtions Welding Machineac dc pulse tig weldercheap thin metal cutting machine CUT-30AC welding machine sell ac CA-201MMA/TIG Welding Machine WS-200200 ampinverter tig welding machineNBC Welding Machine NBC-500MIG CO2 welding machine mig-195AC Arc Portable Welding Machine BX1-250BBX6-300 ac arc welder AC arc welding machineinverter arc welding machine MMA-200cheap igbt mma-250 inverter welding machine