Hydraulic Embossing Machine Hydraulic Press For Door 1000T

Basic Info

Model No.: Yz90

Product Description

Embossing Press, This machine is suitable for all major security door manufacturers and steel wholesale markets, stamping all kinds of flower-type security door panels, it has the advantages of fast, safe and reliable, energy saving, beautiful products and low cost.

The equipment control system adopts advanced automatic control and is equipped with manual control system to make the control system more perfect. It can be exchanged at any time according to the needs. The operation is very simple and convenient.

The 3,000-ton eight-column door embossing hydraulic machine body adopts an eight-column structure, which has good guiding performance and precision guarantee characteristics. The main cylinder is in a six-cylinder arrangement, which makes the work evenly stressed. PLC programming control. Photoelectric protection around the fuselage to ensure personal safety.

The company is equipped with 800T, 1000T and 1200T single-action hydraulic presses for anti-theft door embossing. It has 1200T, 1500T, 2000T and 3000T double-acting hydraulic presses. The double-acting hydraulic press produces the blanking force by the upper cylinder and the top is produced by the lower cylinder. The output is embossed, and the parameters of the blanking force and the ejection force are independently adjustable, and the effect of deep flower formation and wrinkle reduction is particularly obvious.

With Zhengxi, you can put the solutions of the future onto the road. As a global leader in forming technology, we deliver systems, tooling, process expertise and services for the entire automotive industry. We respond to the unique requirements of each customer – with high-quality products and first-class service to support the challenges presented by the market. We are working to exceed the expectations of the future as well, with innovative solutions for the automotive industry.

ZHENGXI provides new ideas in the development of innovative and future-oriented products again and again. This gives our customers an advantage in international competition with efficiency, productivity and preparation for the future.

With Zhengxi, you can put the solutions of the future onto the road. As a global leader in forming technology, we deliver systems, tooling, process expertise and services for the entire automotive industry. We respond to the unique requirements of each customer – with high-quality products and first-class service to support the challenges presented by the market. We are working to exceed the expectations of the future as well, with innovative solutions for the automotive industry.

Proces of manufacturing a door:

Steel Coils → Decoiling → Leveling → Pressing → Cutting → Stacking → Punching → Bending → Assembling and Welding Door Panels → Hot Pressing → Cutting and Welding Door Framess → Transfer Printing → Spraying → Assembling Door and Door Frame.

Features

1.Hydraulic machine that used the hydrostatic pressure to process metal, plastic, rubber, wood, powder and other products .

2. It is commonly used in the pressing process and press forming process, such as: forging, stamping, cold extrusion, straightening, bending, flanging, sheet metal deep drawing, powder metallurgy, press-fit etc.

3.Significant technical and economic advantages in reducing weight, reducing the number of parts and the number of molds, improve the stiffness and strength, reduce production costs, etc.

SPECS of Yz90

| SPECS of Yz90 Single Action embossing machine | ||||||||

| Parameter | unit | Yz90-800T | Yz90-1200T | Yz90-1500T | Yz90-2000T | Yz90-2800T | Yz90-3600T | |

| Nominal Force | KN | 8000 | 12000 | 28000 | 36000 | 28000 | 36000 | |

| Max working pressure of liquid | MPA | 25 | 25 | 25 | 25 | 25 | 26 | |

| Effective table size | Left and right | mm | 1300 | 1300 | 1300 | 1300 | 1400 | 1600 |

| Front and back | mm | 2200 | 2200 | 2200 | 2200 | 2400 | 2600 | |

| Blank holder stroke | mm | 400 | 400 | 400 | 400 | 400 | 400 | |

| Maximum open height | mm | 500 | 500 | 500 | 500 | 500 | 500 | |

| Slider speed | down | mm/s | 100 | 100 | 100 | 100 | 100 | 120 |

| Work | mm/s | 18 | 18 | 15 | 10 | 10 | 10 | |

| Back | mm/s | 80 | 80 | 80 | 80 | 80 | 100 | |

| Motor power | KW | 30 | 37 | 37 | 45 | 60 | 90 | |

| SPECS of Yz90 Double Action embossing machine | ||||||||

| Parameter | unit | Yz90-1200T | Yz90-1500T | Yz90-2000T | Yz90-2800T | Yz90-3600T | ||

| Nominal Force | KN | 12000 | 15000 | 20000 | 28000 | 36000 | ||

| Ejecting force | KN | 6000 | 7000 | 8000 | 10000 | 12000 | ||

| Max working pressure of liquid | MPA | 25 | 25 | 25 | 25 | 26 | ||

| Effective table size | Left and right | mm | 1300 | 1300 | 1300 | 1400 | 1600 | |

| Front and back | mm | 2200 | 2200 | 2200 | 2400 | 2600 | ||

| Blank holder stroke | mm | 400 | 400 | 400 | 400 | 400 | ||

| Ejection stroke | mm | 100 | 100 | 100 | 100 | 100 | ||

| Maximum open height | mm | 500 | 500 | 500 | 500 | 500 | ||

| Slider speed | down | mm/s | 80-120 | 80-120 | 80-120 | 80-120 | 80-120 | |

| Work | mm/s | 20 | 17 | 15 | 15 | 15 | ||

| Back | mm/s | 100 | 100 | 100 | 100 | 100 | ||

| Motor power | KW | 37 | 37 | 44 | 60 | 90 | ||

Workshop

Packaging and delivery

Customer visit

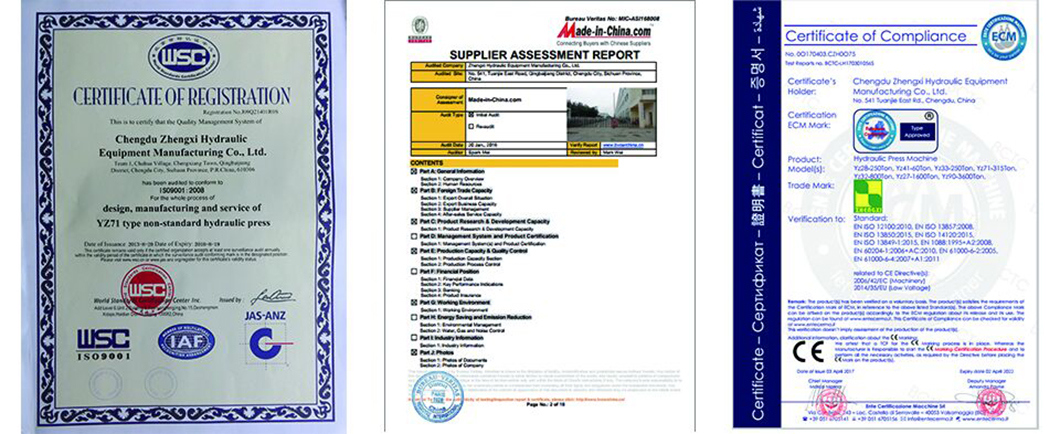

Certificate

After-sale

1.Personnel training

Free training for about one week.

2. After-sale service

One year warranty.During warranty period,free maintenance service can be provided.(except man-made faults or damages arising from irresistible natural factors)

3.Installation

Customers need to pay the commission to our proffessional engineer, and travel expense is on foreign customer.(Including round ticket and accommodation cost)

Our company is an ISO 9001 certified Company, and as an approved supplier for the automotive sector, has also received the CE certificates.This demonstrates that the Quality Assurance System has been fully introduced and adopted, in the interests of providing absolute reliability in our products and careful attention to our customers.

FAQ

1:How can I choose the most suitable machines ?

A: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model .

You can also send us the products drawing ,we will choose the most suitable machines for you .

2: What's your main products of your company?

A: We specialized in all kinds of machines ,such as 1-16000Tons Hydraulic Press,SMC/BMC/GMT/DMC/LFT/GRP/FRP Press,Hydraulic Deep Drawing Press,Hydraulic Forging Press,Metalworking/Stamping Press.

3: Where is our factory located? How can I visit there?

A : Our factory is located in Jiaomei City ,Fujian Province,China. You are warmly welcomed to visit us.

4: What's the MOQ?

A: 1 set .(Only some low cost machines will be more than 1 set )

5: How about your delivery time?

A: Generally 90 days. The specific delivery time depends on the items and the quantity of your order. Sometimes we have some in stock.

6: Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

7: How do you make our business long-term and good relationship?

A: 1.We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

Product Categories : Customization Hydraulic Press > Door Embossing Press Machine