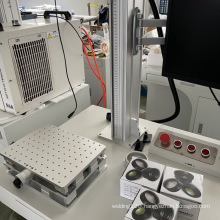

Fuel Filter Infrared Welding Machine

Product Description

Type: Plastic Welders Welding Material: Thermoplastic Welding Time: 0-99s Trademark: NEW STAR HS Code: 8515809090 Current: Alternating Current Welding Area: 250mm Voltage: 380V Origin: China  Infrared welding is a relatively new welding technique used for the many challenging materials and large part

Infrared welding is a relatively new welding technique used for the many challenging materials and large part

Assembly with high strength and hermetic requirements.

During the Infrared welding, both part halves are held rigidly in position near an infrared emitting platen to melt

The joining surfaces. The platen is removed and the part halves driven together and allowed to re-solidify under

Pressure.

It's very similar as the hot plate Welder, but the difference is infrared welder use non-connect heat manner, the

Welding surface will be better than hot plate.

Infrared Weld Strength:

As with the hot plate welding process, infrared welding produces a welded joint which, in many cases, yields a weld strength that is consistently equal to or stronger than any other area of the part. As a result, the weld area can most often be exposed to the same strains and stresses as any other area of the part.

Common Infrared Welded Materials

Acrylonitrile Butadiene Styrene (ABS-Cycolac)

PolyOxy-Methylene (POM-Acetal & Delrin)

PolyAmide (PA-Nylon & Zytel)

PolyButylene Terephthalate (PBT-Valox & Enduran)

PolyEthylene (PE)

PolyEthylene Terephthalate (PET-Polyester)

PolyMethyl MethAcrylate (PMMA-Acrylic & Lucite)

PolyPhenylene Oxide (PPO-Noryl)

PolyPhenylene Sulfide (PPS-Ryton)

PolyPropylene (PP)

PolyStyrene (PS)

PolySulfone (PSO-Udel)

Thermo-Plastic Elastomers (TPE-Santoprene)

Application technology

A variety of successfully realized applications in the automotive, electrical, medical and household appliance

Sectors clearly demonstrates the following benefits: Infrared welding with medium-wave metal-foil emitters is an

Excellent solution for reliable production of welded plastic parts and achieving accurate, particle-free joints

with a high mechanical load capacity. Especially suitable are moldings made of polyolefins (PP, PE), technical

Polymers or synthetic materials with an amorphous and semi-crystalline structure as well as high-temperature

Thermoplastics. This is innovative process technology meeting current market trends towards polymers with

Functional fillers of low viscosity as well as towards constantly increasing customer demands for cleanliness and

The optical aspects of the weld seams.

Contact us if you need more details on Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Welding Machine、Plastic Welding Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Infrared welding is a relatively new welding technique used for the many challenging materials and large part

Infrared welding is a relatively new welding technique used for the many challenging materials and large partAssembly with high strength and hermetic requirements.

During the Infrared welding, both part halves are held rigidly in position near an infrared emitting platen to melt

The joining surfaces. The platen is removed and the part halves driven together and allowed to re-solidify under

Pressure.

It's very similar as the hot plate Welder, but the difference is infrared welder use non-connect heat manner, the

Welding surface will be better than hot plate.

Infrared Weld Strength:

As with the hot plate welding process, infrared welding produces a welded joint which, in many cases, yields a weld strength that is consistently equal to or stronger than any other area of the part. As a result, the weld area can most often be exposed to the same strains and stresses as any other area of the part.

Common Infrared Welded Materials

Acrylonitrile Butadiene Styrene (ABS-Cycolac)

PolyOxy-Methylene (POM-Acetal & Delrin)

PolyAmide (PA-Nylon & Zytel)

PolyButylene Terephthalate (PBT-Valox & Enduran)

PolyEthylene (PE)

PolyEthylene Terephthalate (PET-Polyester)

PolyMethyl MethAcrylate (PMMA-Acrylic & Lucite)

PolyPhenylene Oxide (PPO-Noryl)

PolyPhenylene Sulfide (PPS-Ryton)

PolyPropylene (PP)

PolyStyrene (PS)

PolySulfone (PSO-Udel)

Thermo-Plastic Elastomers (TPE-Santoprene)

Application technology

A variety of successfully realized applications in the automotive, electrical, medical and household appliance

Sectors clearly demonstrates the following benefits: Infrared welding with medium-wave metal-foil emitters is an

Excellent solution for reliable production of welded plastic parts and achieving accurate, particle-free joints

with a high mechanical load capacity. Especially suitable are moldings made of polyolefins (PP, PE), technical

Polymers or synthetic materials with an amorphous and semi-crystalline structure as well as high-temperature

Thermoplastics. This is innovative process technology meeting current market trends towards polymers with

Functional fillers of low viscosity as well as towards constantly increasing customer demands for cleanliness and

The optical aspects of the weld seams.

Contact us if you need more details on Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Welding Machine、Plastic Welding Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Infrared Welding Machine

Premium Related Products

Other Products

Hot Products

DC MMA Machine for Tube UseIGBT Inverter AC/DC TIG Welding MachineIGBT Inverter Pulse TIG Welding Machine (WSM7-500)Inverter Carbon-Arc Air Gouging MachineInverter DC Multi-funtions Welding Machineac dc pulse tig weldercheap thin metal cutting machine CUT-30AC welding machine sell ac CA-201MMA/TIG Welding Machine WS-200200 ampinverter tig welding machineNBC Welding Machine NBC-500MIG CO2 welding machine mig-195AC Arc Portable Welding Machine BX1-250BBX6-300 ac arc welder AC arc welding machineinverter arc welding machine MMA-200cheap igbt mma-250 inverter welding machine